Terazaki Hamono - Tsume Scissors

There are only a few people in the world. One of the craftsmen who can make grip scissors with total fire makes it Nigiri scissors (nigiri scissors) "Kenshi"

Stock Item

"Total Fire Construction" (Sohizukuri) of Terasaki blade.

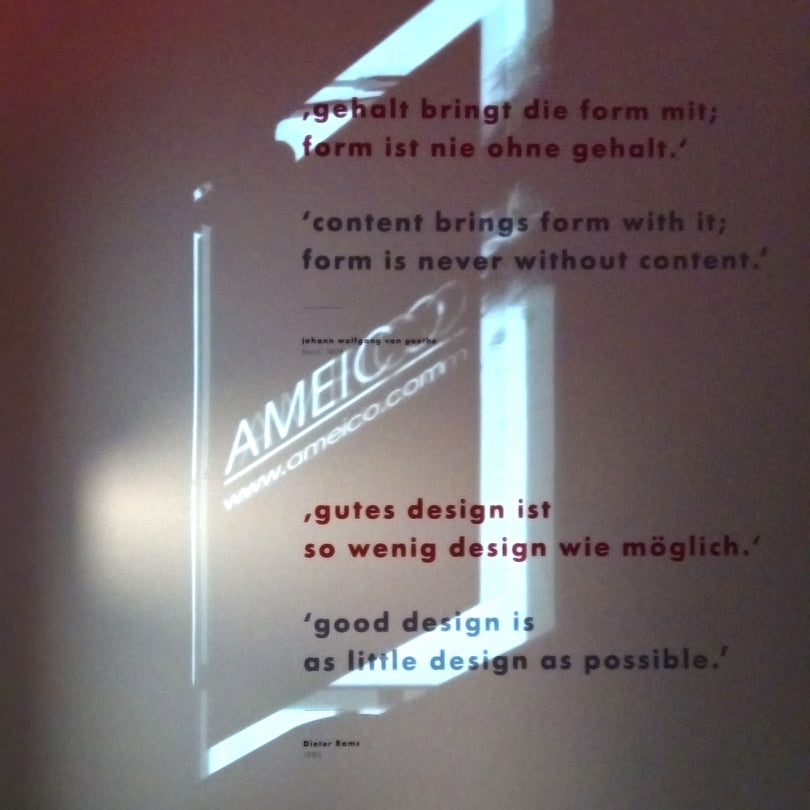

It is a traditional manufacturing method that beats heated iron and steel without using a mold and makes everything such as thickness and shape by hand.

Most of the grip scissors made in Japan are made by machine, purchased from "composite steel" with steel (hagane) on iron, and manufactured while processing them. In the Terasaki blade, the composite material described above is not purchased, but iron and steel are heated with a flame of about 1,000 degrees and beaten with a hammer. At the same time, the shape will be prepared with a single hammer. In this way, the manufacturing method that is made from the joining of iron and steel is called "total fire construction". The joining of iron and steel is an extremely difficult technology, and it is an inefficient manufacturing method that produces many failures, but it can be manufactured with detail, such as spring strength and grip, comfort of use and shape.

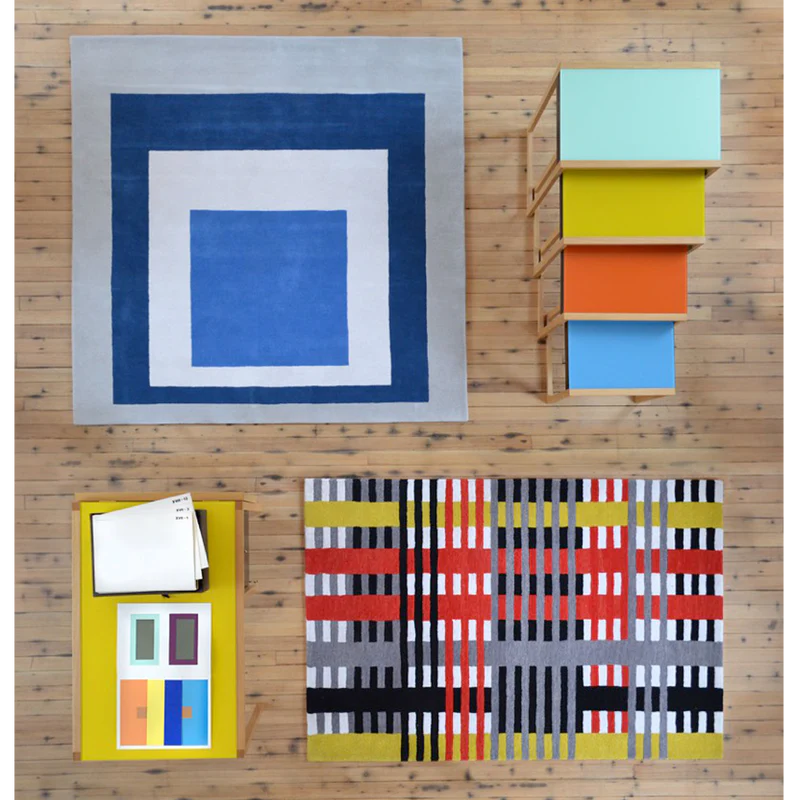

The representative grip scissors of the Kenshi series have three shapes: "claws/long blades/tin tapered". The exclusive usage method is not clearly divided by shape, and it seems to vary depending on the region and industry. "Taper" is used by many people, from sewing work to craftsmen of Japanese sweets. In addition, the "claw" has a short blade and a very easy-to-handle shape. Grip scissors are scissors that can be used for a lifetime if you use them carefully. It is used in many situations, such as their own work, hobbies, and gifts.

Material: Steel

Made in Japan

Design by: Kenshi Terasaki

Born and raised in Kumamoto, he spent years working a conventional job. Yet, the dream he had nurtured since childhood never faded. At the age of 36, driven by a quiet determination, he left his hometown and relocated to Hyogo. There, under the guidance of a revered master, he immersed himself in learning a rare and ancient blade-making technique—one that had nearly vanished from the world.

After years of rigorous training, he purchased a small workshop just ten minutes from his mentor’s, marking the beginning of his independent journey. Among his creations, the nigiri scissors stood out—not the kind found in 100-yen shops or craft stores, but a far rarer breed. These were total fire-made nigiri scissors, forged with a centuries-old method now preserved only by his master and himself.

Their rarity made them elusive, sought after by those who understood their value. Unlike mass-produced tools, these scissors were crafted with an artisan’s touch—each one shaped by feel, down to 0.1mm precision. He focused not only on the visible surface but also on the unseen essence of the materials, ensuring every pair carried the soul of its maker. Mass production was never his goal; instead, he chose the path of devotion, creating blades that whispered of tradition, mastery, and quiet excellence.